Table of Contents

Barcodes have become essential for any business, serving as a powerful and necessary tool in order fulfillment operations.

Many third-party logistics (3PL) companies rely on barcodes to run warehouse processes efficiently.

Keep reading to learn more about shipping barcodes and how they can help boost your eCommerce operations.

What Is a Barcode?

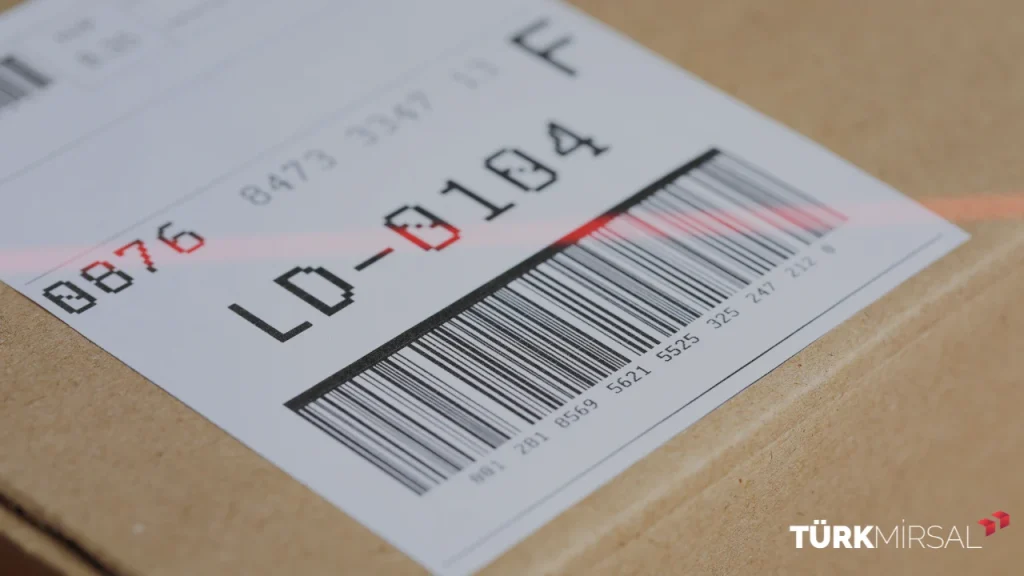

A barcode is a unique pattern of parallel lines with varying thicknesses designed for machine reading. These codes are printed on products to support accurate inventory control.

Shipping barcodes contain crucial information about the product. By scanning the code, handlers can access product details such as type, category, exact delivery address, customer information, shipping method, and even payment method.

Barcodes are scanned at every stage of the delivery process—from picking the product to delivering it to the final customer.

Use Cases of Barcodes

Businesses use barcodes to plan and manage online order shipments or organize eCommerce inventory. Because of this, scanning barcodes at every stage of the shipping cycle is essential. Below are the main use cases of barcodes in shipping and fulfillment centers:

Receiving Inventory at Fulfillment Centers

When inventory arrives at warehouses or fulfillment and distribution centers, barcodes on packages are scanned to retrieve complete information and confirm receipt of shipments.

Handing Orders to Carriers

Once an order is picked, packed, and prepared for shipping, the barcode on the shipping label is scanned. Carriers also scan this code before the package leaves the shipping facility.

Receiving Returned Orders

When a returned package arrives at a 3PL facility, the barcode on the shipping label is scanned before the item is accepted. This ensures that the correct product has been received—an important step since the refund process typically begins at this stage.

Types of Barcodes

Barcode formats generally fall into three main categories:

1. Alphanumeric Barcodes

These barcodes can store large amounts of data and are used for tracking and data collection. They hold more information than numeric-only barcodes.

2. Numeric Barcodes

A simpler type of barcode that stores limited information, often used for basic inventory management tasks.

3. Data Matrix Barcodes

These compact, square-shaped codes are ideal for labeling small items. They closely resemble QR codes in appearance and offer fast readability, making them popular in logistics for small products.

Barcode Usage Categories

Shipping Barcodes

These barcodes appear on labels attached to all types of packages. 3PL partners scan them when receiving shipments into inventory, when shipping wholesale orders, or when sending products directly to consumers. Shipping barcodes help track inventory status and identify delivery exceptions during transit.

Product Barcodes

In addition to appearing on individual products, these barcodes are used to label storage locations such as bins, shelves, and pallets. They enhance warehouse organization, improve accuracy, and ensure that the right products are shipped to the right customers.

Importance and Benefits of Barcodes in Shipping

Barcodes play a fundamental role in warehouse management. Here are the key benefits they provide to improve operational efficiency:

1. Faster Order Processing

Handling a large number of orders without scanning technology is nearly impossible. Without barcode systems, accurately recording the contents of each package, product details, and customer information becomes extremely difficult.

Barcodes significantly increase processing speed and reduce the likelihood of errors when shipping large volumes of products daily.

2. Error Reduction

Manually entering inventory data can lead to numerous mistakes. Barcode technology eliminates the need for manual entry and ensures extremely accurate data collection during receiving, picking, shipping, and other inventory operations.

3. Increased System Efficiency and Mobility

Modern barcode scanners are not restricted to fixed locations. Wireless scanners allow warehouse workers to move freely, reducing walking time within large fulfillment centers and enabling faster order processing.

4. Improved Dashboards and Inventory Management

Fulfillment centers generate large amounts of paperwork-based data, making real-time evaluation challenging. When barcodes are integrated with a warehouse management system (WMS), they provide real-time information about key warehouse operations.

This reduces manual work and lowers the chances of errors, especially when handling high-volume orders.

Conclusion

Barcodes have become indispensable in shipping operations, especially within warehouses and fulfillment centers. This technology offers numerous benefits that improve inventory flow, enhance accuracy, and increase overall efficiency for businesses.

Adopting barcode systems is now essential for any operation aiming to streamline logistics and achieve smooth, efficient warehouse performance.